CARBON STEEL PIPE CARBON SEAMLESS STEEL PIPE CARBON STEEL SEAMLESS PIPE

Description

Seamless Steel Pipe is made from a solid round steel ‘billet’ which is heated and pushed or pulled over a form until the steel is shaped into a hollow tube. The seamless pipe is then finished to dimensional and wall thickness specifications in sizes from 1/8 inch to 32 inch OD. Carbon Steel Seamless Pipes / Tubes Carbon steel is an alloy consisting of iron and carbon. The percentage of carbon in the steel affects the hardness, strength of elasticity and ductility of carbon steel. Seamless carbon steel pipe or solid steel ingot is made of the capillary tube through the hole, then through the hot-rolled, cold rolled or cold call is made. Seamless carbon steel pipe in China's steel industry has an important position. Seamless carbon steel pipe material is a round tube, pipe cutting machine embryos to go through cutting about 1 m of length blank, and sent by conveyor belt furnace heating. Billet is fed into the heating furnace, the temperature is about 1200 degrees Celsius. Fuel is hydrogen or acetylene. Furnace temperature control is the key issue. Round tube came out to punch through the machine through air pressure. Generally more common punch is tapered roll perforation machine, the punch high production efficiency, product quality, large diameter hole expansion, can wear a variety of steel. Perforation, round tube has been on three-roll cross rolling, rolling or extrusion. Squeezed off the tube after sizing. Sizing by high-speed rotary cone drill holes into the billet to form a tube. Pipe diameter by the sizing mill to determine the length of the drill diameter. After the pipe through the sizing into the cooling tower, cooling by water spray, steel after cooling, should be straightening. After the steel belt sent by straightening metal testing machine (or pressure test) for internal testing. If the pipe internal cracks, bubbles and other problems will be detected. After the pipe but also through strict quality control manual selection. Steel quality, the use of spray paint numbers, specifications, production lot number. By a crane into the warehouse.

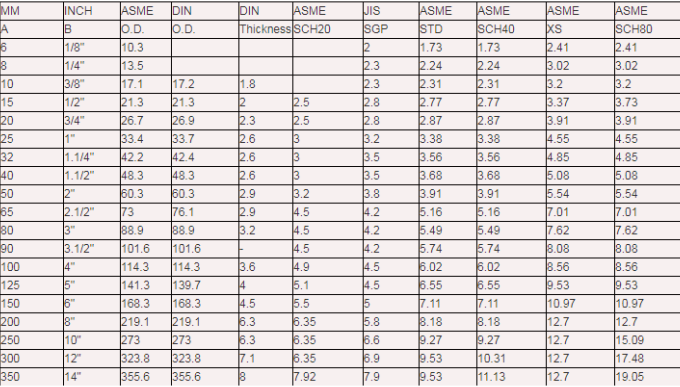

The wall thickness of seamless pipe

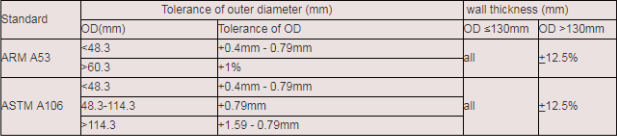

Tolerance of Outer Diameter and Wall thickness

Specification

|

Standard |

Description |

| ASTM A179/A179M | Seamless cold drawn low alloy steel heat exchanger and condenser tubes. |

| API 5L | Line pipe. |

| ASTM A53M | Black & Zinc Coated Welded and Seamless Steel Pipe. |

| ASTM A106M | Seamless carbon steel pipe for high temperature service. |

| ASTM A105M | Carbon steel forgings for piping applications. |

| ASTM A234M | Piping fittings of wrought carbon steel and alloy steel for moderate and high temperature service. |

Standard

|

Standard |

Type of pipe |

Class |

Grade |

|

API SPEC 5L ISO 3183 |

SMLS |

PLS1 |

L245B, L290 X42, L320 X46 , L360 X52, L390 X56, L415 X60, L450 X65, L485 X70 |

|

PLS2 |

L245N BN, L290N X42N, L320N X46N, L360N X52N, L390N X56N, L415N X60N, L360Q X52Q, L390Q X56Q, L415Q X60Q , L485Q X70Q |

||

|

PLS2 Sour Environment |

L245NS BNS, L290NS X42NS, L320NS X46NS L360NS X52NS, L390NS X56NS, L415NS X60NS, L360QS X52QS, L390QS X56QS, L415QS X60QS L485QS X70QS |

||

|

WELD |

PLS1 |

L245B, L290 X42, L320 X46, L360 X52 L390 X56, L415 X60, L450 X65, L485 X70 |

|

|

PLS2 |

L245M BM, L290M X42M, L320M X46M, L360M X52M, L390M X56M, L415M X60M, L450M X65M, L485M X70M, L555M X80M, |

|

Standard |

Grade |

|

ASTM A 53 M |

A , B |

|

ASTM A 106M |

A, B, C |

|

JIS G 3454 |

STPG 370, STPG 410 |

|

JIS G 3455 |

STPG370, STPG410, STPG480 |

|

JIS G 3456 |

STPG370, STPG410, STPG480 |

Grade: Chemical Composition (%):

|

Standard |

Grade |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Cu |

Mo |

V |

|

ASTMA 53M |

A |

≤0.25 |

- |

≤0.95 |

≤0.05 |

≤0.045 |

≤0.40 |

≤0.40 |

≤0.40 |

≤0.15 |

≤0.08 |

|

B |

≤0.30 |

- |

≤1.20 |

≤0.05 |

≤0.045 |

≤0.40 |

≤0.40 |

≤0.40 |

≤0.15 |

≤0.08 |

|

|

ASTM A 106M |

A |

≤0.25 |

≥0.10 |

0.27-0.93 |

≤0.035 |

≤0.035 |

≤0.40 |

≤0.40 |

≤0.40 |

≤0.15 |

≤0.08 |

|

B |

≤0.30 |

≥0.10 |

0.29-1.06 |

≤0.035 |

≤0.035 |

≤0.40 |

≤0.40 |

≤0.40 |

≤0.15 |

≤0.08 |

|

|

C |

≤0.35 |

≥0.10 |

0.29-1.06 |

≤0.035 |

≤0.035 |

≤0.40 |

≤0.40 |

≤0.40 |

≤0.15 |

≤0.08 |

|

|

JIS G 3454 |

STPG 370 |

≤0.25 |

≤0.35 |

0.30-0.90 |

≤0.040 |

≤0.040 |

- |

- |

- |

- |

- |

|

STPG 410 |

≤0.30 |

≤0.35 |

0.30-1.00 |

≤0.040 |

≤0.040 |

- |

- |

- |

- |

- |

|

|

JIS G 3455 |

STS 370 |

≤0.25 |

0.10-0.35 |

0.30-1.10 |

≤0.035 |

≤0.035 |

- |

- |

- |

- |

- |

|

STS 410 |

≤0.30 |

0.10-0.35 |

0.30-1.40 |

≤0.035 |

≤0.035 |

- |

- |

- |

- |

- |

|

|

STS 480 |

≤0.33 |

0.10-0.35 |

0.30-1.50 |

≤0.035 |

≤0.035 |

- |

- |

- |

- |

- |

|

|

JIS G 3456 |

STPT 370 |

≤0.25 |

0.10-0.35 |

0.30-0.90 |

≤0.035 |

≤0.035 |

- |

- |

- |

- |

- |

|

STPT 410 |

≤0.30 |

0.10-0.35 |

0.30-1.00 |

≤0.035 |

≤0.035 |

- |

- |

- |

- |

- |

|

|

STPT 480 |

≤0.33 |

0.10-0.35 |

0.30-1.00 |

≤0.035 |

≤0.035 |

- |

- |

- |

- |

- |

Painting&Coating

Surface treatment of steel pipe: In order to improve the service life of oil pipeline, surface treatment is usually carried out to facilitate the firm combination of steel pipe and anticorrosive coating.Common processing methods are: cleaning, tool derusting, pickling, shot blasting derusting four categories.

1.Cleaning Grease, dust, lubricant, organic matter adhered on the surface of steel pipe, usually using solvent, emulsion to clean the surface.However, the rust, oxide skin and welding slag on the surface of the steel pipe cannot be removed, so other treatment methods are needed.Tool rust removal Steel pipe surface oxide, rust, welding slag, can use steel wire brush to clean and polish the surface treatment.

2.Tool derusting can be divided into manual and power, manual tool derusting can reach Sa 2 level, power tool derusting can reach Sa3 level.If the surface of steel pipe is attached with a particularly strong oxide skin, it may be impossible to remove the rust with the help of tools, so we need to find other ways.

3.Pickling Common pickling methods include chemistry and electrolysis.But only chemical pickling is used for pipeline corrosion protection.Chemical pickling can achieve a certain degree of cleanliness and roughness on the surface of steel pipe, which is convenient for subsequent anchor lines.Usually as a shot (sand) after reprocessing.

4.Shot blasting for rust removal.By high power motor drive the high-speed rotating blades, steel grit, steel shot, segment, minerals and other abrasive wire under the action of centrifugal force on steel pipe surface spray and mass ejection, thoroughly remove rust, oxides and dirt on one hand, on the other hand, steel pipe under the action of abrasive violent impact and friction force, to achieve the required uniform roughness.Among the four treatment methods, shot blasting and derusting is an ideal treatment method for pipe derusting. Generally, shot blasting and derusting are mainly used for inner surface treatment of steel pipe, and shot blasting and derusting are mainly used for outer surface treatment of steel pipe.

Packing&Loading

Spray paint

Waterproof packaging