News

-

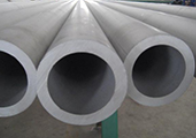

Seamless tube production equipment

There are many kinds of seamless tube (smls) production equipment according to the seamless steel tube production process. However, regardless of the rolling, extrusion, top pressing or spinning seamless steel tube manufacturing process, the billet heating equipment is inseparable, so the billet ...Read more -

Six processing methods commonly used for seamless pipes

There are six main processing methods for seamless pipes (SMLS): 1. Forging method: Use a swage forging machine to stretch the end or part of the pipe to reduce the outer diameter. Commonly used swage forging machines include rotary type, connecting rod type, and roller type. 2. Stamping method: ...Read more -

Advantages of tubes

Advantages of tubes What is a tube? Tubes are ideal for transporting fluids or protecting electrical or optical connections and wires. Although there are slight differences, the words “pipe” and “tube” are virtually identical – in general, a tube has higher technical standards than a pipe. Today’...Read more -

What are the details of the thick-walled steel pipe before use

1. Thick-walled steel pipe cutting: According to the actual required pipeline length, the pipe should be cut with a metal saw or a toothless saw. When water welding is used in the cutting process, the raw materials should be protected accordingly. When cutting, fire-resistant and heat-resistant m...Read more -

The main purpose of thick wall steel pipe

There is a great difference between a thick-walled steel pipe and a thin-walled steel pipe in terms of wall thickness. If the diameter of the steel pipe wall is greater than 0.02, we generally call it a thick-walled steel pipe. Thick-walled steel pipes have a very wide range of applications. Owin...Read more -

Matters needing attention in use of thick-walled steel pipe

The wall thickness can be called a thick-walled steel pipe. There are some doubts about this. It depends on the ratio of the outer diameter of the steel pipe to the wall thickness of the steel pipe. For example, a steel pipe with a diameter of 50 mm, 10 mm can be regarded as a thick-walled steel ...Read more -

Large diameter coated steel pipe

Coated steel pipe is manufactured by coating plastic based on large-diameter spiral welded pipe and high-frequency welded pipe. The maximum pipe diameter is 1200mm. Polyvinyl chloride (PVC), polyethylene (PE), epoxy can be coated depending on different needs. Resin (EPOZY) and other plastic coati...Read more -

Precautions for Purchasing Large Diameter Straight Seam

Before purchasing large-diameter straight seam steel pipes (LSAW), you should follow the pre-designed specifications, lengths, materials, wall thicknesses, welding standards and weld requirements, which must be communicated well before purchasing. 1. The first is the specification. For example, 8...Read more -

Three ways to ensure smoothness as required when producing straight seam steel pipes

1. Rolling mold: The general method of rolling mold is to press the glass powder into a glass mat. Before the straight seam steel pipe is rolled, the glass mat is clamped between the steel and the center of the rolling mold, to make the glass pad in the center. Under the effect of conflict, the s...Read more -

10 Ways to remove burrs from seamless steel tubes

Burs are ubiquitous in the metalworking process. No matter how advanced and sophisticated equipment you use, it will be born with the product. This is mainly due to the plastic deformation of the material and the generation of excessive iron filings at the edges of the processed material, especia...Read more -

How to ensure the quality of steel pipe products

Our main products are high-frequency straight seam welded steel pipes and double-sided submerged arc welded steel pipes, etc., which are widely used in medium and low pressure fluid transmission pipelines such as oil, natural gas, water, steam, gas, etc., as well as structural steel pipes for pil...Read more -

Representation methods and welding methods of welded

How to indicate the grade of welding steel: Welding steel includes carbon steel for welding, alloy steel for welding, stainless steel for welding, etc. The way to indicate the grade is to add the symbol “H” to the head of each type of welding steel grade. For example H08, H08Mn2Si, H1Cr18Ni9. For...Read more